Sieve Analysis of Fine Aggregates – Introduction

Sieve analysis of fine aggregates is one of the most important tests performed on-site. Aggregates are inert materials that are mixed with binding materials such as cement or lime for the manufacturing of mortar or concrete. It is also used as fillers in mortar and concrete. Aggregates size varies from several inches to the size of the smallest grain of sand. The Aggregates(fine + coarse) generally occupy 60% to 75% of the concrete volume or 70% to 85% by mass and strongly influence the concrete’s freshly mixed and hardened properties, mixture proportions, and economy. All Aggregates pass IS 4.75 mm sieve is classified as fine Aggregates.

All aggregate technicians use the sieve analysis (gradation test) to determines the gradation (the particle size distribution, by size, within a given sample) in order to determine compliance with design, production control requirements, and verification specifications. Used in conjunction with other tests, the sieve analysis is very good to control and quality acceptance tool.

Gradation meaning the distribution of particle sizes within the total range of size. Gradation can be identified on a graph as well-graded, uniform, or gap graded (sometimes called skip graded) which are described below :

- Well graded means sizes within the entire range are in approximately equal amounts, although there will be a very small amount of the largest and smallest particles.

- Uniform gradation means that a large percentage of the particles are of the same size.

- Gap graded or skip graded means that most of the particles are large in size or small in size with very few particles of an intermediate size.

Objectives:

The whole procedure of sieve analysis is to determine the particle size distribution of the fine aggregates and determine whether it is suitable to use in concrete mixing.

Test Equipment

- A series of IS sieves

- A pan and a shovel

Fig. Pan and Shovel - Balance or scale with an accuracy to measure 0.1 percent of the weight of the sample.

Fig.Weighing Balance - Mechanical sieve shaker

Fig. Mechanical Sieve Shaker

Experimental Procedure for Sieve Analysis

- Weighed the sample to exactly 1000g.

- First of all, we have to clean all the sieves using a wire brush to be clear of aggregates stuck in some gaps.

- Then we have to prepare the sieves onto the shaking machine from top to bottom, by the size from biggest (4,75mm) to smallest (0.075mm).

- The sample is sieved by using the set of IS Sieves for 10 minutes.

- After the sieving is done, the aggregates on each sieve are weighed individually.

- Cumulative weight passing through each sieve is calculated as a percentage of the total sample weight.

- The same procedure is followed for two more samples.

The formula for calculating the percentage retained and percentage passing:

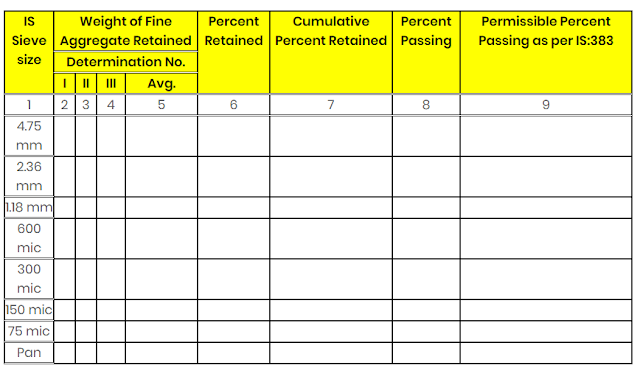

TABLE: DETERMINATION OF PARTICLE SIZE DISTRIBUTION OF FINE AGGREGATES

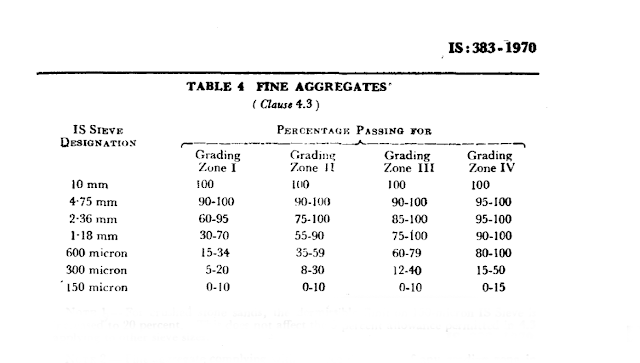

The percentage passing weight so obtained shall than be compared with the permissible values given in the IS 383. The standard table in IS code shows the permissible values of percentage passing for different grading zones i.e., Zone I, Zone II, Zone III, and Zone IV. The zone of the sand thus is determined by comparing the observed percentage passing values with the permissible values given in the IS 383.

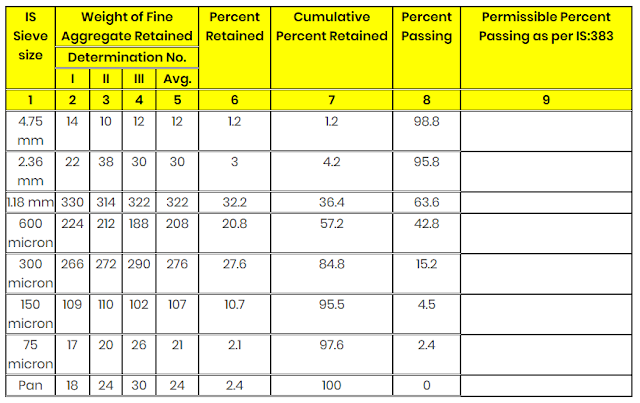

Data and Calculation for a random sample

- Determination of Particle Size Distribution of Fine Aggregates:

- Total Weight of Fine Aggregates = 1000g

RESULT :

In this case, in comparison with Table 4 IS:383, it can be concluded that the Fine Aggregate corresponds to Grading Zone II.

Good work for summarizing the sieve analysis of fine aggregates. Can you also summarize the sieve analysis of cement and make its curve?